Embossing has long been a favored technique in the realms of design, artistry, and crafting, adding depth, texture, and visual interest to a variety of surfaces. With the advent of 3D printing technology, the creation of embossing plates has undergone a remarkable transformation, offering new avenues for creativity and expression. Let’s embark on a journey into the captivating world of 3D printed embossing plates, where innovation meets tradition.

Contents

Understanding the Essence of Embossing Plates

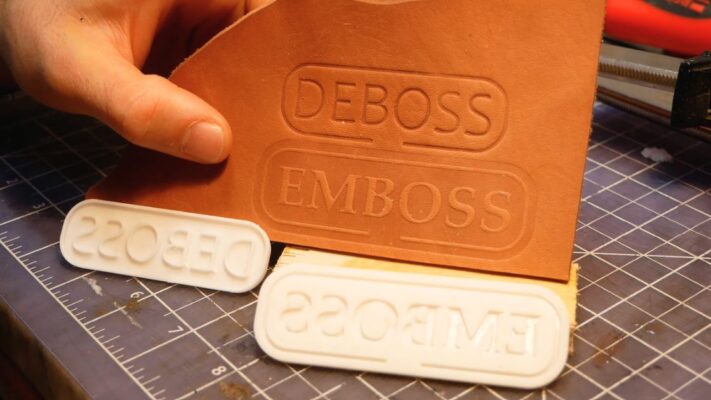

Embarking on a creative project often involves seeking ways to elevate the visual appeal of a piece. Embossing plates serve as indispensable tools in this endeavor, enabling artists, designers, and enthusiasts to impart intricate designs onto surfaces such as paper, cardboard, metal, and fabric. By applying pressure, these plates leave behind raised impressions that capture the imagination and delight the senses.

What You Need for 3D Printed Embossing Plates

To embark on the journey of creating 3D printed embossing plates, you’ll need the following:

- 3D Modeling Software: Begin by creating or selecting a design for your embossing plate using 3D modeling software. This software allows you to visualize and refine your design before moving on to the printing stage.

- 3D Printer: Invest in a reliable 3D printer capable of producing high-quality prints with fine details. Consider factors such as printing speed, resolution, and material compatibility when selecting a printer.

- Printing Material: Choose a suitable printing material based on your project requirements and desired finish. Common options include PLA, ABS, PETG, and resin, each offering unique properties and characteristics.

- Slicing Software: Utilize slicing software to prepare your 3D model for printing by generating the necessary toolpaths and instructions for the printer. Adjust settings such as layer height, infill density, and print speed to achieve optimal results.

The Process of Creating 3D Printed Embossing Plates

The journey from concept to creation involves the following steps:

Design Preparation

Use 3D modeling software to design your embossing plate, taking into account factors such as pattern complexity, depth, and scale. Ensure that the design is suitable for 3D printing and can withstand the embossing process.

Slicing and Printing

Import your design into slicing software and configure the necessary parameters for printing. Once prepared, transfer the file to your 3D printer and initiate the printing process. Monitor the print closely to ensure accuracy and quality.

Post-Processing

Once printing is complete, remove the 3D printed embossing plate from the build platform and inspect it for any imperfections. Perform any necessary post-processing steps such as sanding, priming, or coating to enhance the surface finish and durability of the plate.

Testing and Refinement

Test the embossing plate on various materials to assess its performance and effectiveness. Make any adjustments or refinements to the design as needed, iterating until the desired results are achieved.

Applications and Potential

The versatility of 3D printed embossing plates opens up a world of possibilities across diverse industries and creative pursuits:

- Art and Design: Artists and designers can utilize embossing plates to add intricate textures and patterns to sculptures, paintings, and mixed media artworks, enhancing their visual impact.

- Packaging and Branding: Businesses can create custom embossing plates to embellish packaging materials such as boxes, bags, and labels, elevating their brand identity and perceived value.

- Educational Tools: Educators can use 3D printed embossing plates as teaching aids to demonstrate concepts in art, science, and engineering, fostering hands-on learning and creativity.

- Personal Expression: Enthusiasts and hobbyists can explore the world of embossing as a means of self-expression, creating personalized stationery, greeting cards, and decorative items.

In conclusion, 3D printed embossing plates represent a harmonious fusion of traditional craftsmanship and cutting-edge technology, offering limitless possibilities for artistic expression, innovation, and exploration. Whether used for commercial applications, educational endeavors, or personal projects, these intricately crafted plates serve as vessels of creativity and inspiration in the hands of makers and creators.

Related Posts