Coasters are not just practical items for protecting surfaces from moisture and heat; they also offer an opportunity for creative expression and personalization. In this article, we explore how 3D printing technology can be utilized to craft customized coasters, adding a unique touch to any home decor. From design selection to printing and finishing, we provide a comprehensive guide to creating bespoke coasters that reflect individual style and preferences.

Contents

Choosing the Design

The first step in crafting personalized coasters with 3D printing is selecting the design. Whether it’s geometric patterns, intricate artwork, or thematic motifs, the design options are virtually limitless. Design files can be sourced from online repositories, created using graphic design software, or even hand-drawn and digitized. The key is to choose a design that resonates with the intended aesthetic and complements the existing decor.

Software and Preparation

Once the design is chosen, it needs to be prepared for 3D printing. Design software such as Tinkercad, Blender, or Autodesk Fusion 360 can be used to import the design file and optimize it for printing. This may involve adjusting dimensions, adding or removing elements, and ensuring that the design is suitable for 3D printing. Additionally, the design needs to be converted into a compatible file format, such as STL or OBJ, before proceeding to the printing stage.

Material Selection

Selecting the right material is crucial for achieving the desired appearance, durability, and functionality of the coasters. Common materials used in 3D printing include PLA, ABS, PETG, and resin. PLA is a popular choice for coasters due to its ease of printing, wide range of colors, and biodegradability. However, other materials may be preferred for specific applications, such as heat-resistant or water-resistant properties. Consideration should also be given to factors such as texture, finish, and compatibility with the chosen design.

Printing Process

With the design finalized and the material selected, it’s time to start the 3D printing process. This can be done using a personal 3D printer or by utilizing online 3D printing services. Before printing, it’s important to calibrate the printer settings, including layer height, infill density, and print speed, to ensure optimal results. Depending on the complexity of the design and the chosen material, the printing process may take several hours to complete.

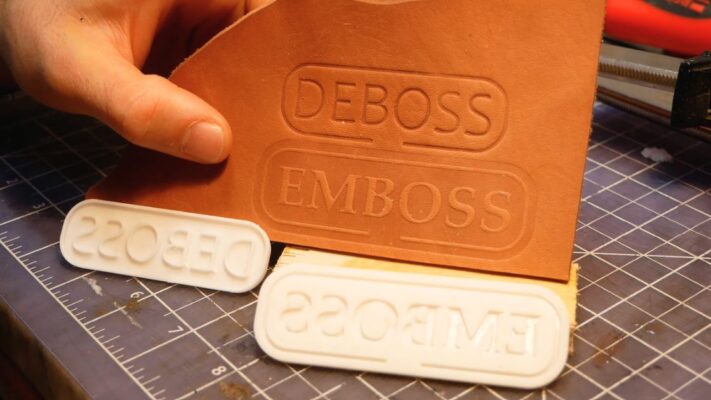

Post-Processing and Finishing

Once the coasters are printed, they may require post-processing to remove any support structures, imperfections, or rough edges. This can be done using sandpaper, files, or other finishing tools. Additionally, users may choose to apply surface finishes or coatings, such as paint, varnish, or epoxy resin, to enhance the appearance and durability of the coasters. Finally, the coasters can be fitted with non-slip backing or cork padding to prevent them from scratching surfaces and provide added stability.

Crafting personalized coasters with 3D printing technology offers a fun and creative way to add a personal touch to home decor. By leveraging digital design tools, materials, and printing techniques, enthusiasts can bring their ideas to life in tangible and functional forms. Whether it’s for personal use, gifts, or promotional items, the possibilities are endless when it comes to creating custom coasters with 3D printing. With a little imagination and ingenuity, anyone can transform ordinary coasters into unique and eye-catching pieces that reflect their individual style and personality.

Related Posts